[biginfopane textcolor=”#ffffff” title=”System Description”][/biginfopane]

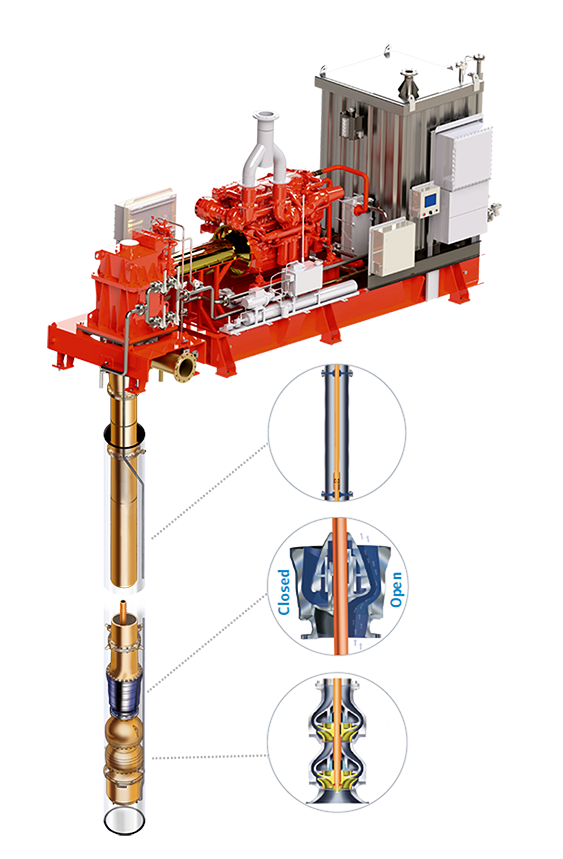

The fire water pump system is a fully mechanical driven self contained deep well pump system designed according to NFPA20. The diesel engine is connected to right angle gearbox with a cardan shaft or a flexible coupling on a common base frame driving a long shaft submerged centrifugal pump. All necessary auxiliary equipment will be provided on or near the skid. The cooling is water taken from pump discharge and the complete system is independent of external cooling water

The lineshaft pump is designed according to API610 to maximize the life time and availability. The pump and gear is designed for easy pump rotor vertical position adjustment and for easy alignment of the pump

The fully mechanical drive makes this system the most power efficient, light weight and compact solution compared to electrical and hydraulic deep well configuration. The mechanical design results in minimum fail modes with package control requirements.

The package requires layout considerations because the pump and driver mechanically connected on common skid, which may restrict the use of this pump configuration. There are very few interface points from the system to the user system due to common skid for both pump and driver. Start up of the system is relatively straight forward due to low inertia with no need for excess power. This system can easily be modified to meet zone 2 requirements.

The angle gear is a custom made gear designed according to NFPA 20. The gear is equipped with reinforced thrust bearing taking up the thrust forces of the pump rotor. A non reverse ratchet and hollow shaft design is incorporated. The pump speed can be selected with the bevel gear in order to optimize the pump duty point.

The combination of high power efficiency, the low inertia during start up and the possibility to optimize the pump speed often result in a smaller driver size compared to electric and hydraulic driver designs. The benefit is cost, weight and space savings.

A non return valve can optionally be fitted to the pump to prevent water hammering during start up. The valve secures a water filled riser during standby. The small valve leakage will be refilled by a small seawater line from the seawater or fire water ring main. The valve is typically used for larger capacity systems from approx. >2000m3/h

The system has historically been used on fixed platforms and onshore installations due to layout restrictions on floaters.[clear]