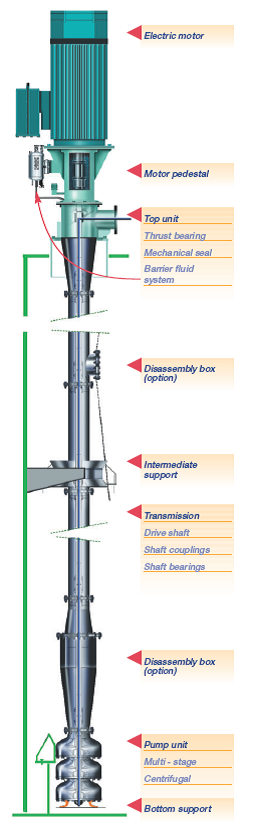

Cargo Lineshaft – Component Descriptions

Component Descriptions

The pump unit is a radial split building block arrangement with one to six stages, with solid hub impellers. Both impeller (as an option) and pump bowl can be fitted with wear rings. The pump shaft is supported by sleeve bearings at every stage, which are lubricated by the pumped fluid.

Pump unit is driven by deck mounted driver. Drive shaft is sectionalised, enclosed in the riser column and supported at the flange connections by spider bearings. Pump axial thrust is taken by deck head mounted thrust bearing or by the bearing in the driver. Oil or grease lubricated anti friction thrust bearing is used.

Mechanical seal is fitted at deck head and permits complete accessibility for maintenance purposes. Pump drive is through a spacer coupling to facilitate easy replacement of seals and thrust bearing.

Heavy duty motor pedestal flanged to pump deck head and fitted with ample access openings to spacer coupling, thrust bearing and mechanical seal.

Non sparking coupling protection (option) is easily removable for coupling inspection.

Pump bowls

The pump bowls are of the diffusor type. Each diffusor has an outlet flange screwed to the next diffusor or first riser column. Together with the riser columns and discharge bend on deck, they are designed for the required working pressure.

Riser columns

The riser columns bring the pumped fluid up to deck level. Each column is a flanged pipe, which supports the shaft journal bearings through spider bearings at each flange connection.

Nozzles

As standard discharge nozzle is supplied with a 150 lbs ANSI B16.5 flange with a 1/16″ raised face.

Pumps can be furnished with other flange ratings and facing upon request. Standard orientation is horizontal.

Suction nozzle is normally submerged into a basin. As an option pumps can be delivered with a bucket around the pump unit, making it possible to connect the pump inlet to a pipeline.

Dynamic seal

A mechanical seal is fitted in deck head (discharge bend).

Shaft

The shaft which is machined and ground to required dimensions, is of ample size to transmit the required power and prevent excessive deflection.

Long shaft pumps have the drive shaft enclosed in the riser columns. Several intermediate shafts connected by sleeve couplings, transmit power to the pump unit. Each shaft is normally two times the column section length. This means that each shaft is supported by two journal bearings. As an option, shaft length can be made equal to column length if the dismantling height on deck is limited.

Impeller

The impeller is single suction and designed with a large eye area to ensure low NPSH requirements and thus reduce the possibility of cavitations.

Casing wear rings

The casing wear rings are inserted in the pump bowl with a slight interference fit and secured with a hollow head setscrew.

Throat bushing

Long shaft pumps have a throat bushing fitted in the deck head to minimize leakage around the shaft. This can be a straight sleeve or a labyrinth seal. Both solutions ensure low pressure on the back up seal or mechanical seal.

Shaft sleeve

Shaft sleeves are keyed to prevent rotation and are axially secured between impellers and shaft lock nut. Thus securing the impellers in the correct axial position, as well as protecting the shaft from wear under the bearings in the pump unit. As an option, the intermediate shafts can also be delivered with protective sleeves under the journal bearings in the riser.

Gaskets

O-ring type gaskets are provided between the pump bowls, column risers and deck head, which allows metal to metal assembly ensuring correct fit.

Bearings

The pumps have axial thrust taken by a deck head mounted thrust bearing or by the bearing in the driver. Either oil or grease lubricated anti-friction thrust bearing is used.

Journal bearings in riser and pump unit are of the product lubricated sleeve type. Normally these bearings are of impregnated carbon with excellent dry running capabilities. Impregnation material and carbon/graphite quality will be dependent upon pumped fluid.

Coupling

Pumps with an axial bearing fitted in the deck head will be furnished with a spacer type flexible coupling designed for easy mounting/dismounting.

If the axial bearing is located inside the driver, the coupling will be of a rigid axial adjustable type.

For both solutions a mechanical seal and/or thrust bearing may be changed on site without dismounting the electric motor.